Third Party Inspection Process

Quality inspection is important for companies that purchase products. When their products are ready, they usually request a quality inspection. Quality inspection has three types: first-party , second-party and third-party inspection. First-party inspection is the inspection done by the manufacturer. Second-party inspection is the quality inspection done by the worker from client company. We call the client company buyer or purchaser. Third-party inspection is the inspection by the external inspection agency entrusted by the second party customer. Next we will know more details about inspection and third party inspection process.

Basic Description of Inspection

Before talking about the process of inspection, I will show you some basic term in inspection. First one is Sample Size. In quality inspection, the best way is to inspect all products. However, it is impossible. In most import and export trades, the quantity of products are very large. Testing 100% products will spend a lot of time of quality controller. Therefore, the sample size appears. Sample size is relatively reasonable sampling level. The other one is AQL(Acceptable Quality Level). This level specifies the number of rejected products we can accept. When all products meet this standard, the inspection is done. Below are the tables.

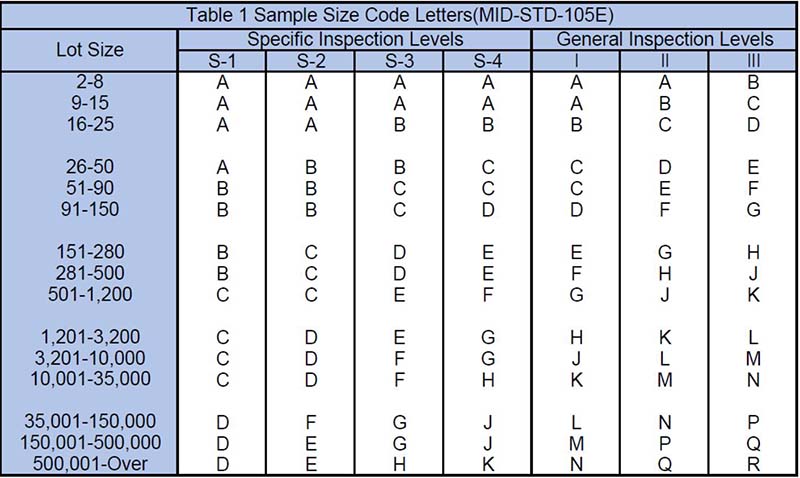

Table 1

This table is Sample Size Code Letters. We can find the fianl sample size according to the quantity of our products. Normally, the levels that third party adopt is S-2 and Level-Ⅱ. If the quantity is 12500 pcs, we will search in interval 10,001-35,000. According to General Inspection Leval Level-Ⅱ, the final sample size code letter is M. Then we will check Table 2: AQL. Show as below.

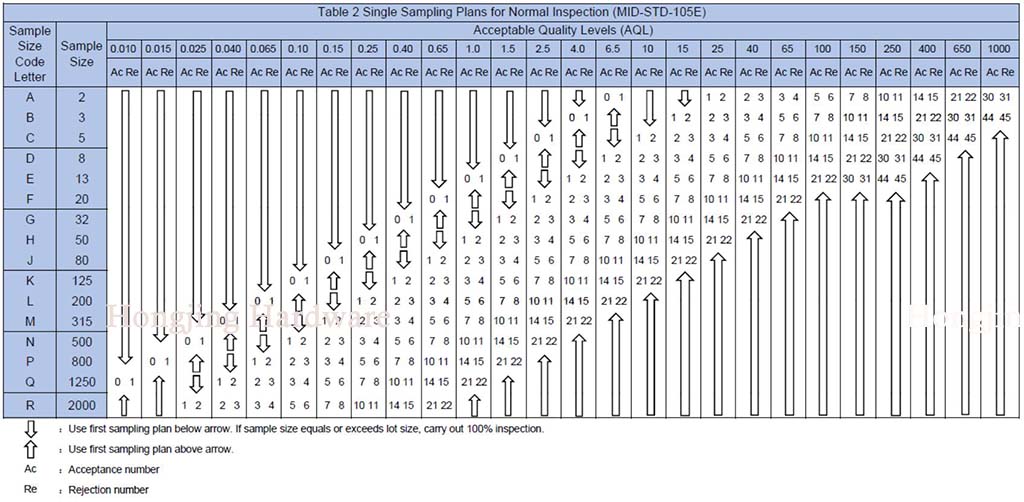

Table 2

We can see in this table. The letter M shows the sample size is 315. It means that we need to inspect 315 pcs products out of total 12500 pcs products. There are two columns of Ac Re under each value of the acceptance level. When the total number of such defects ≤Ac value, the goods are acceptable; when the total number of such defects ≥Re value, the quality agency will reject the goods. The suppliers will reproduce the goods. Different agencies have different AQL standard. Normally, the AQL standard is Cr. 0; Ma. 2.5; Mi. 4.0.

Short Description about Defect Level

Cr, Ma and Mi represent defect level. Cr is Critical. It refers to the products which may cause harm to human body or against laws or regulations. Ma means Major. It refers to the products that have defects on function or appearence. Mi represents Minor. It refers to the products that have minor defects on products surface.

Third Party Inspection Process

Here, we will talk about the third party inspection process.

Step 1: The quality agency will discuss with customers about the detailed requests while they receive an inspection application. They confirm carefully about sample size and AQL. And tell these information to the inspector.

Step 2: Inspector will contact the factory at least 1 day before the inspection day. The inspector will confirm if the supplier produced all goods as the request.

Step 3: On the inspenction day, inspector will first read the Integrity Statement to the factory.

Step 4: Inspector will confirm completion of the goods as a whole. He or she will take photos of total pallets. Take some pictures of every single pallet.

Step 4: Carry out box inspection.

Step 5: Check the information of outer box, inner box and products. He or she will take pictures of shipping mark on every box. He or she will check the item No., product name and manufacturer information. All information are correct, finish this step. If there are some information wrong, suppliers need to correct.

Step 6: The woker will check the product appearence according to Level-Ⅱ. Check the fuction and size according to S-2.

Step 7: Count the number of defect products. Confirm with the suppliers. If the defects exceed the standard, the inspection cannot pass. Factory need to rework.

Step 8: After the inspection, prepard the test report and send to auditors.

Step 9: Send the report to customers’ e-mail.

Conclusion

These are the whole third party inspection process. It is easy but strict. Normally, the inspectors will come to our warehouse and test. Due to the COVID-19, they can test them through video. Our company has experienced many times inspection. Everytime we do a great job. All aspects are good including package, shipping mark and product quality. You can trust our company. We will provide you our best products and service.

Welcome to cooperate with Shanghai Hongjing Hardware.